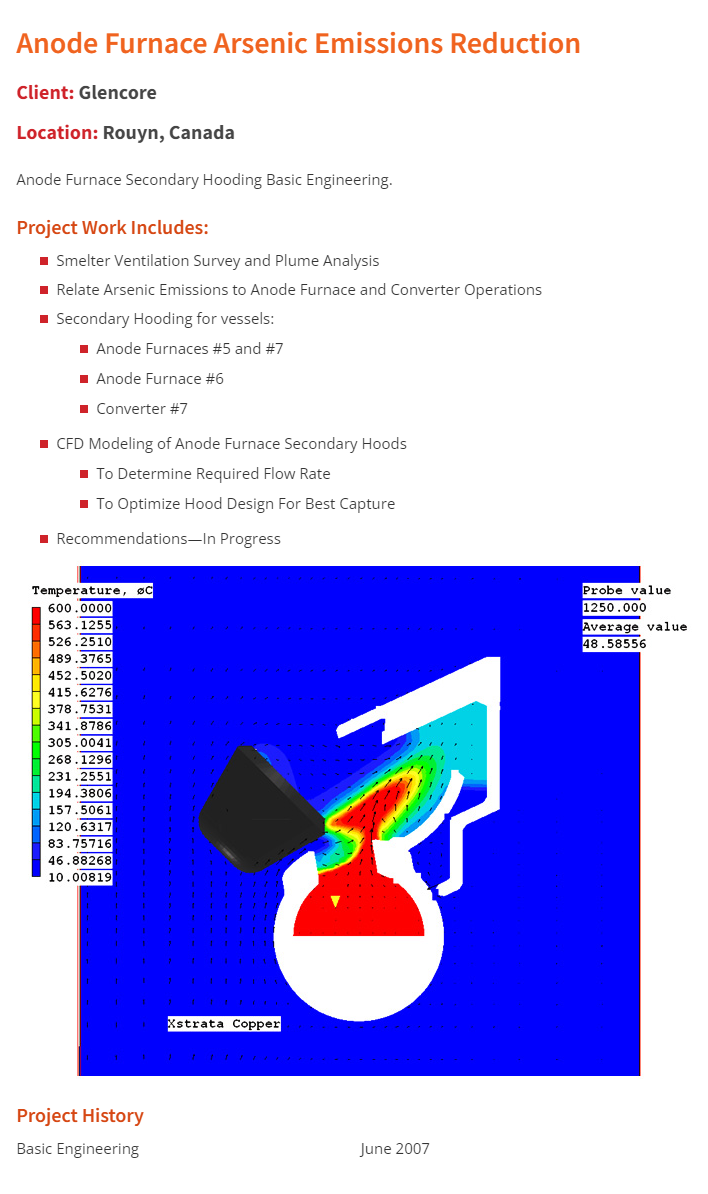

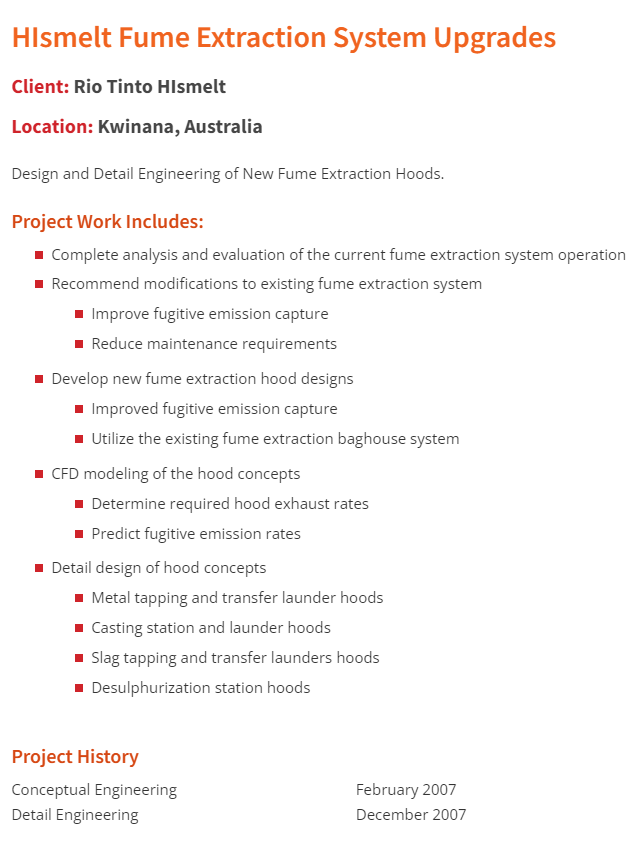

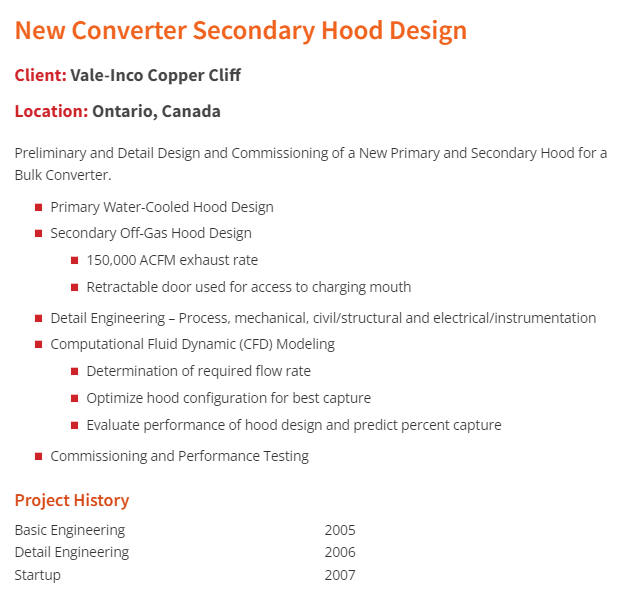

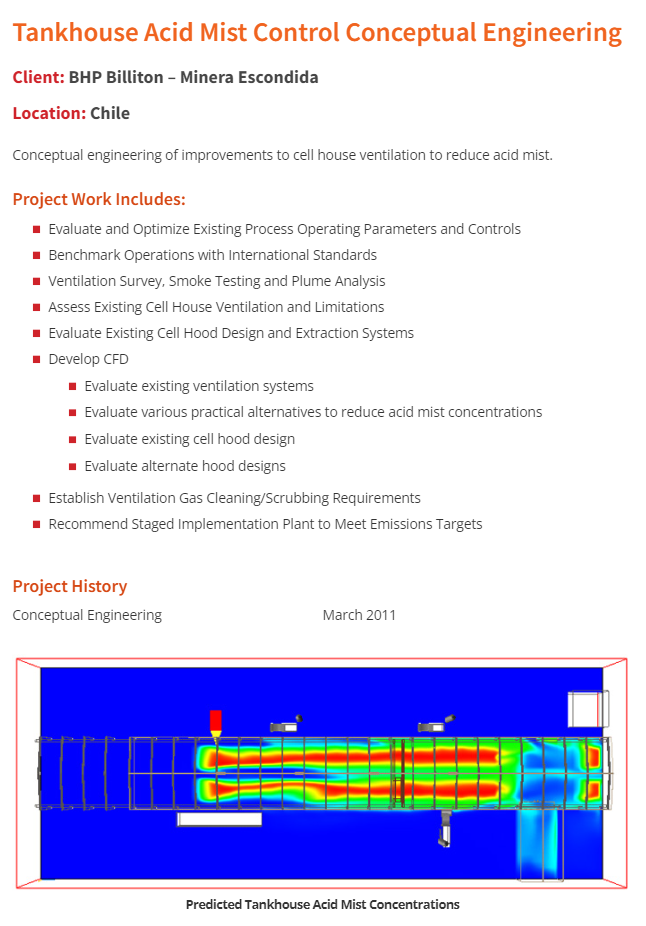

Computational Fluid Dynamic (CFD) Modeling

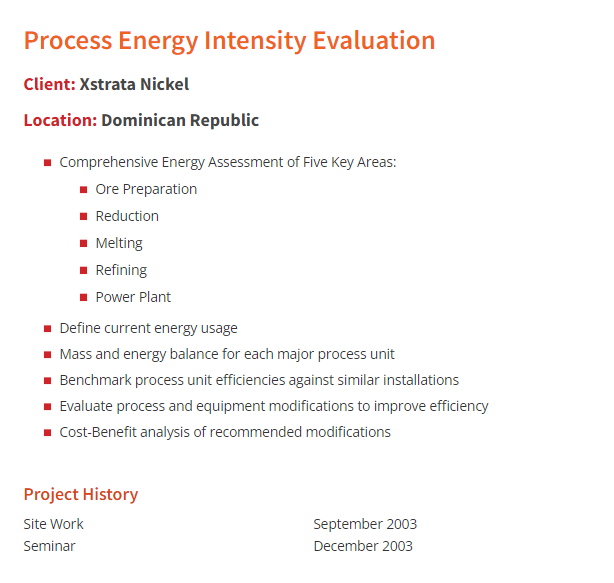

- Predicting heat and contaminant exposure levels

- Evaluating performance of ventilation systems in process plants

- Predicting airflow patterns and contaminant migration paths

- Optimizing primary and secondary capture hood performance

- Predicting and optimizing process gas mixing and combustion

- Evaluating burner configuration and selection

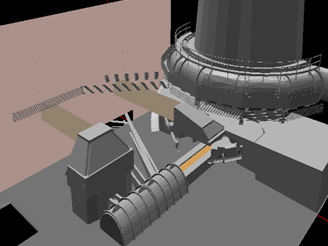

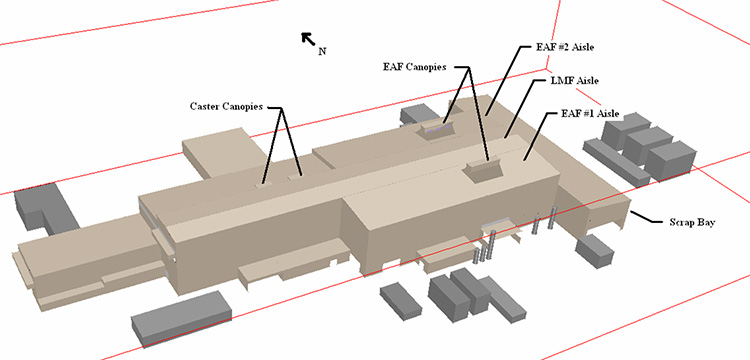

Melt Shop Overall Geometry

The geometry was developed in the Phoenics package model editor using drawings provided by the melt shop

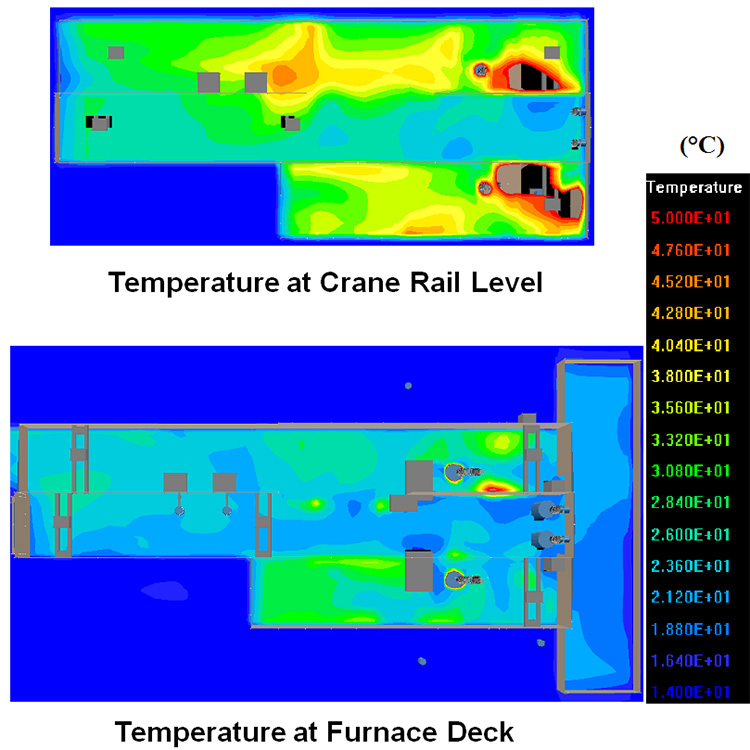

- Provides a Quantitative Estimate of Fume Capture

- Provides a Quantitative Estimate of Temperature at any Elevation Inside Building

- Model Validated Using Field Measurements

- Able to Test Many Scenarios Efficiently

- Effects of Wind Direction and Ambient Temperature on Cross Drafts and Hood Fume Capture Performance

Charge Existing

Charge Future

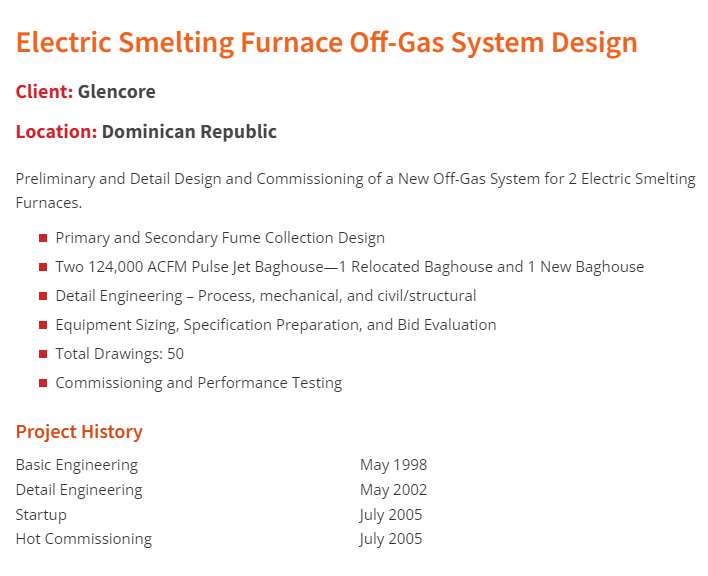

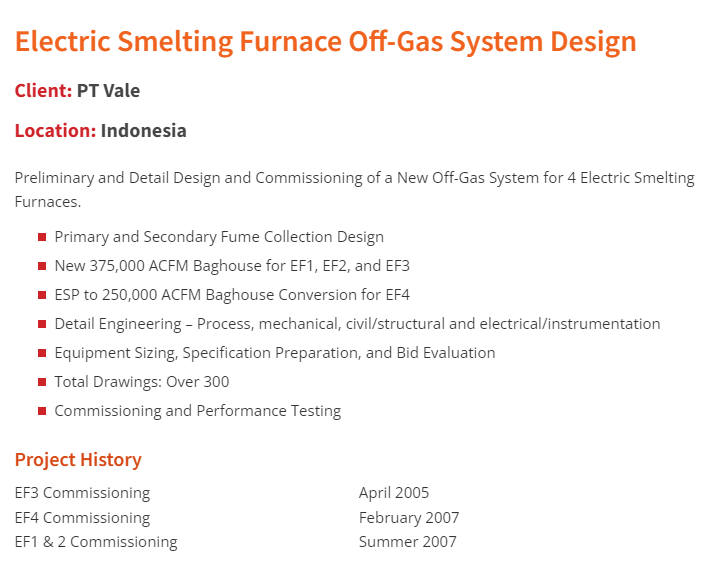

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.

Process Gas Handling &

Cleaning System Design

Fugitive Emission

Control

Drummond-GCT

Water Cooled Head

Process Vessel

Design

Existing Asset Life Cycle

Optimization

Process Evaluation &

Optimization

Bulk Material Handling

System Design

Water & Wastewater

Treatment

Project Development

Services

Technology Commercialization &

Integration

Computational Fluid

Dynamic Modeling

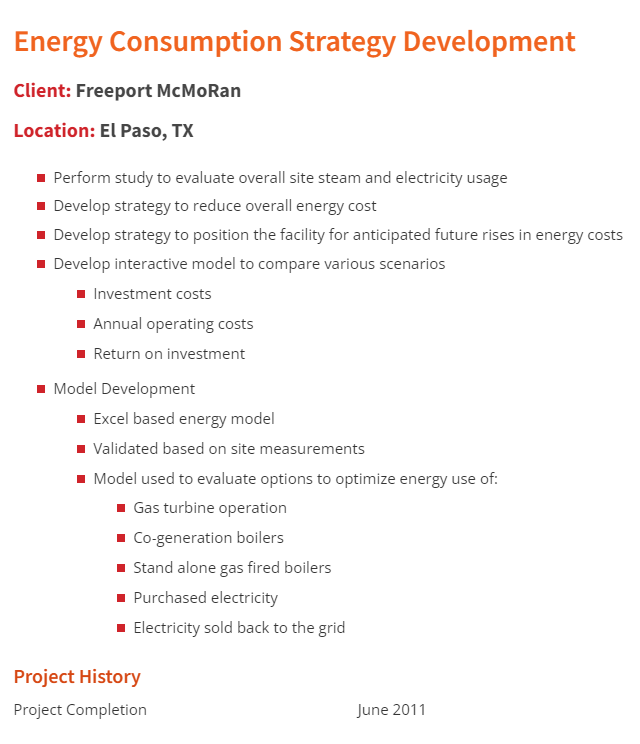

Energy

Services

GCT provides waste heat recovery solutions, plant energy audits, decarbonization roadmap development, and many more energy services.

Energy

Optimization

Plant Energy

Audits

Fuel Conversion

Solutions

Project Development

Services

Technology Commercialization

& Integration

Decarbonization Roadmap

Development

Waste Heat

Recovery Solutions

Hydrogen

Services

GCT is proud to provide hydrogen services for applications such as metallurgical reduction, industrial thermal heat, and power generation.

Hydrogen Technology

Development

Hydrogen Risk & Safety

Management

Hydrogen Technology

Integration & Implementation

Let's Make The World a Better Place, Together

Follow Us

GlossyFox Web Design