Process Gas Handling & Cleaning System Design

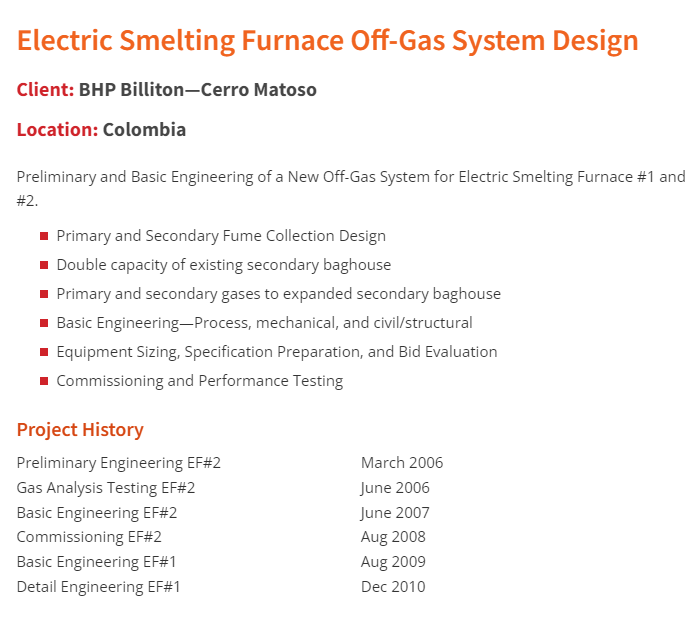

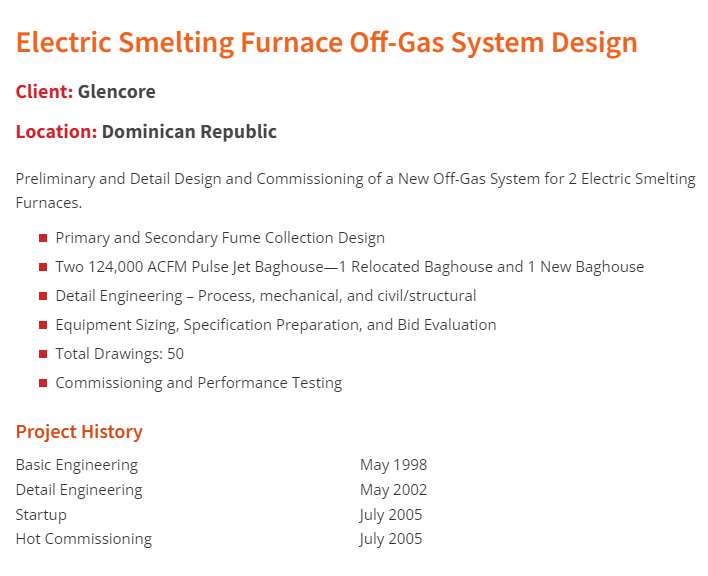

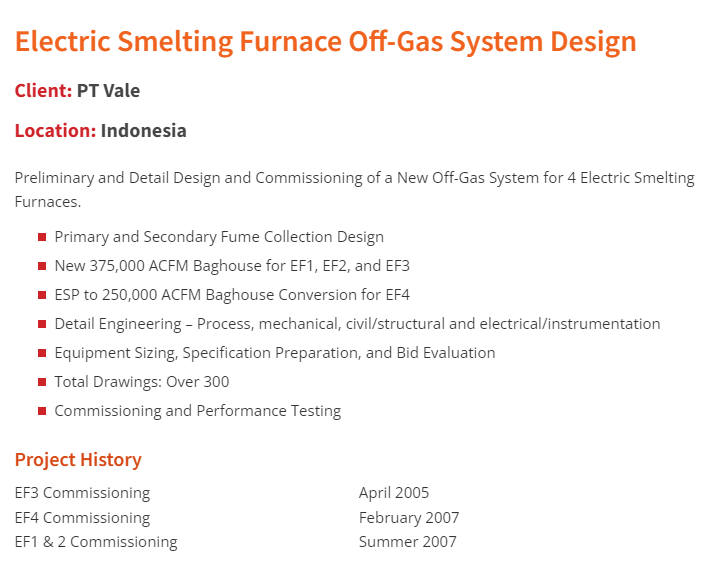

GCT has extensive experience in gas handling system design for both ferrous and non-ferrous metallurgical furnaces, including drying, calcining / roasting, smelting / melting, heating, and refining. Specific capabilities surrounding process gas handling system design include:

- Process gas characterization

- Process gas heat recovery, including waste heat boilers, heat exchangers, thermal fluids, and power generation

- Process gas conditioning, including combustion chambers, water-cooled ducts, and evaporative coolers

- Flue gas desulfurization (FGD)

- Process NOx control

- Gas cleaning system equipment selection, including baghouses, scrubbers, dry and wet electrostatic precipitators (ESPs)

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.

Process Gas Handling &

Cleaning System Design

Fugitive Emission

Control

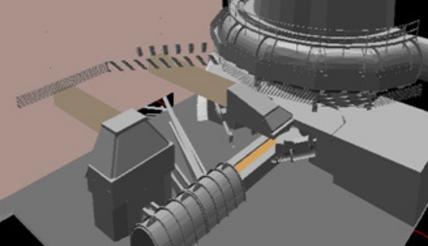

Drummond-GCT

Water Cooled Head

Process Vessel

Design

Existing Asset Life Cycle

Optimization

Process Evaluation &

Optimization

Bulk Material Handling

System Design

Water & Wastewater

Treatment

Project Development

Services

Technology Commercialization &

Integration

Computational Fluid

Dynamic Modeling

Energy

Services

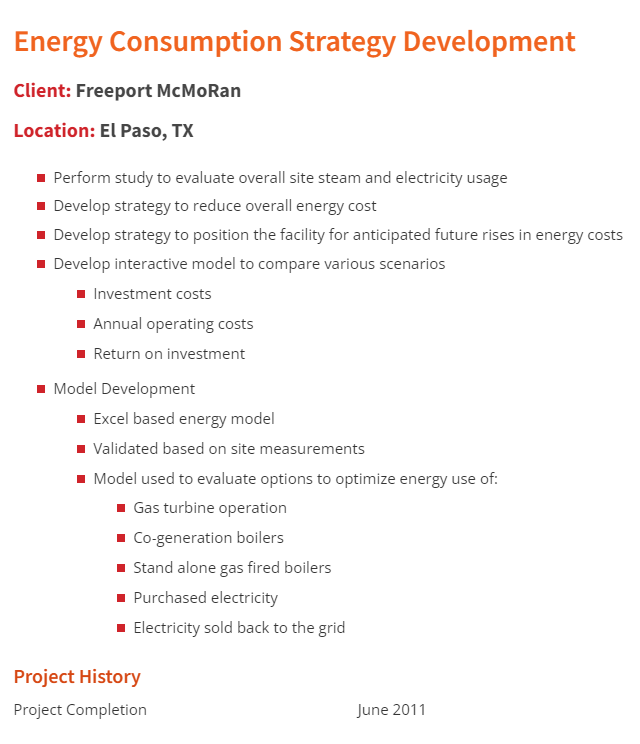

GCT provides waste heat recovery solutions, plant energy audits, decarbonization roadmap development, and many more energy services.

Energy

Optimization

Plant Energy

Audits

Fuel Conversion

Solutions

Project Development

Services

Technology Commercialization

& Integration

Decarbonization Roadmap

Development

Waste Heat

Recovery Solutions

Hydrogen

Services

GCT is proud to provide hydrogen services for applications such as metallurgical reduction, industrial thermal heat, and power generation.

Hydrogen Technology

Development

Hydrogen Risk & Safety

Management

Hydrogen Technology

Integration & Implementation

Let's Make The World a Better Place, Together

Follow Us

GlossyFox Web Design