Energy: Featured Project

Waste Heat Recovery

Key Project Features:

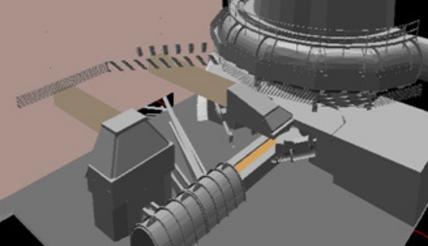

- Install a new direct ORC system for re-heat furnace

- Construction completed in 17 months after receipt of order

- Power production up to 0.6 MW

- Zero reported accidents or incidents

Total Investment: ~5M USD

Integrated Steel Mill Energy Footprint Optimization

Key Project Features:

- Developed interactive model to compare plant wide energy requirements for various scenarios.

- Optimized the steam system (generation, distribution and use)

- Developed recommendations for the best utilization of available resources

- Identified project opportunities designed to reduce energy consumption and external fuel purchases

- Evaluated viable option based on project readiness, ease of implementation, risks and project economics

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.

Process Gas Handling &

Cleaning System Design

Fugitive Emission

Control

Drummond-GCT

Water Cooled Head

Process Vessel

Design

Existing Asset Life Cycle

Optimization

Process Evaluation &

Optimization

Bulk Material Handling

System Design

Water & Wastewater

Treatment

Project Development

Services

Technology Commercialization &

Integration

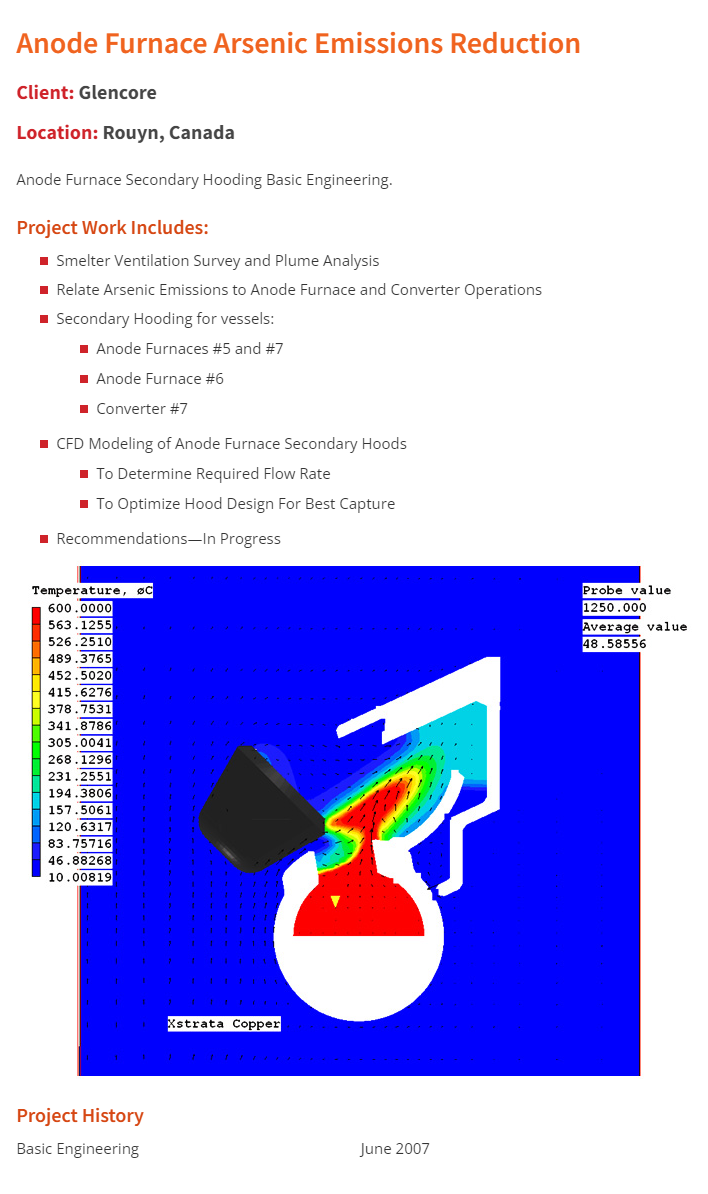

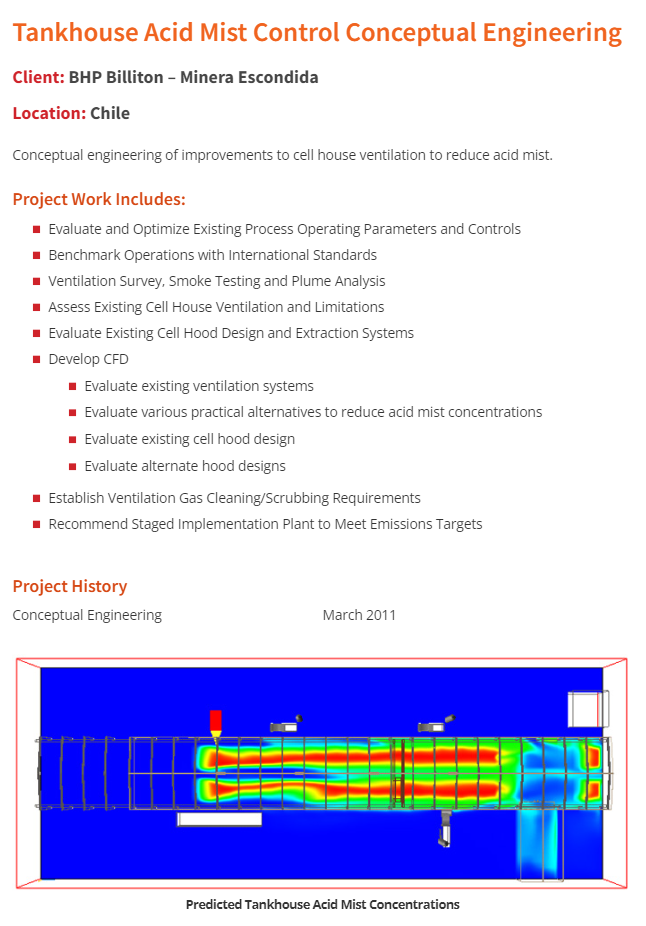

Computational Fluid

Dynamic Modeling

Energy

Services

GCT provides waste heat recovery solutions, plant energy audits, decarbonization roadmap development, and many more energy services.

Energy

Optimization

Plant Energy

Audits

Fuel Conversion

Solutions

Project Development

Services

Technology Commercialization

& Integration

Decarbonization Roadmap

Development

Waste Heat

Recovery Solutions

Hydrogen

Services

GCT is proud to provide hydrogen services for applications such as metallurgical reduction, industrial thermal heat, and power generation.

Hydrogen Technology

Development

Hydrogen Risk & Safety

Management

Hydrogen Technology

Integration & Implementation

Let's Make The World a Better Place, Together

Follow Us

GlossyFox Web Design