Gas Cleaning: Featured Project

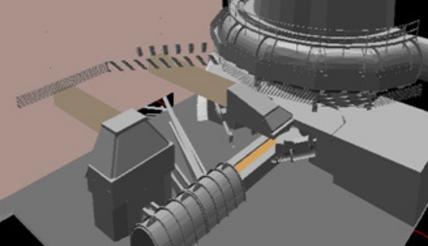

Converter Retrofit Project

Landmark EPA legislation created new SO2 NAAQS. GCT developed the project from Concept through to EPCM for the Asarco Hayden Copper Smelter (Arizona) to improve SO2 and dust emissions from smelter operations to achieve the new ambient air concentration limit of 75 ppb SO2 on a 1-hour average.

Key Project Features:

- Replace 5 converter operation with 3 larger converters, complete with controls, flux and scrap feed systems, ladles and tuyere punchers.

- Improve hooding and off gas collection systems to achieve > 99% sulfur fixation.

- Install new converter primary gas handling including spray chambers, ESP, fans, water cooled hoods, secondary hoods and damper controls.

- Retrofit 1911 era building to accommodate new larger converters, ancillary equipment and install a roof canopy system for tertiary ventilation.

- Upgrade plant infrastructure to include: blast air blowers, air compressors, cooling towers, and electrical substation.

- Install new acid plant wet gas cleaning and sludge drying system.

Total Investment: ~200M USD

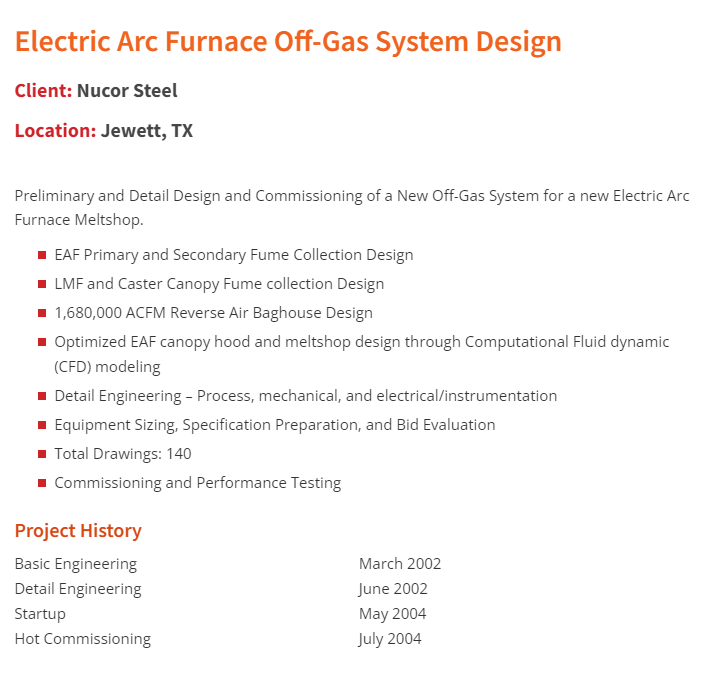

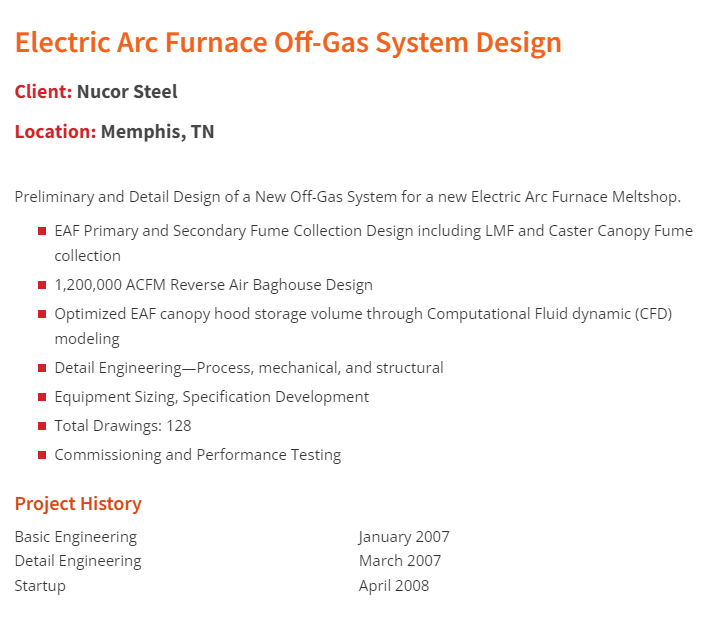

Electric Arc Furnace Off-Gas System Design

GCT provided engineering and design services to Nucor to refurbish and re-open a shuttered steel mill in Memphis, TN. The air pollution control system was engineered to meet strict environmental requirements for a non-attainment area.

Key Project Features:

- Establish process design for the new APC system

- Computational Fluid Dynamics modeling to optimize EAF canopy hood arrangement and exhaust requirements

- Develop basic design and procurement packages for the Direct Evacuation Control (DEC) system for the EAF, baghouse system, I.D. fans and other purchased components

- Develop detailed engineering drawings and engineering works packages for fabricated components

- Continued support during procurement and construction

- Commissioning assistance and optimization

Total Investment: ~35M USD

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.

Process Gas Handling &

Cleaning System Design

Fugitive Emission

Control

Drummond-GCT

Water Cooled Head

Process Vessel

Design

Existing Asset Life Cycle

Optimization

Process Evaluation &

Optimization

Bulk Material Handling

System Design

Water & Wastewater

Treatment

Project Development

Services

Technology Commercialization &

Integration

Computational Fluid

Dynamic Modeling

Energy

Services

GCT provides waste heat recovery solutions, plant energy audits, decarbonization roadmap development, and many more energy services.

Energy

Optimization

Plant Energy

Audits

Fuel Conversion

Solutions

Project Development

Services

Technology Commercialization

& Integration

Decarbonization Roadmap

Development

Waste Heat

Recovery Solutions

Hydrogen

Services

GCT is proud to provide hydrogen services for applications such as metallurgical reduction, industrial thermal heat, and power generation.

Hydrogen Technology

Development

Hydrogen Risk & Safety

Management

Hydrogen Technology

Integration & Implementation

Let's Make The World a Better Place, Together

Follow Us

GlossyFox Web Design